Features

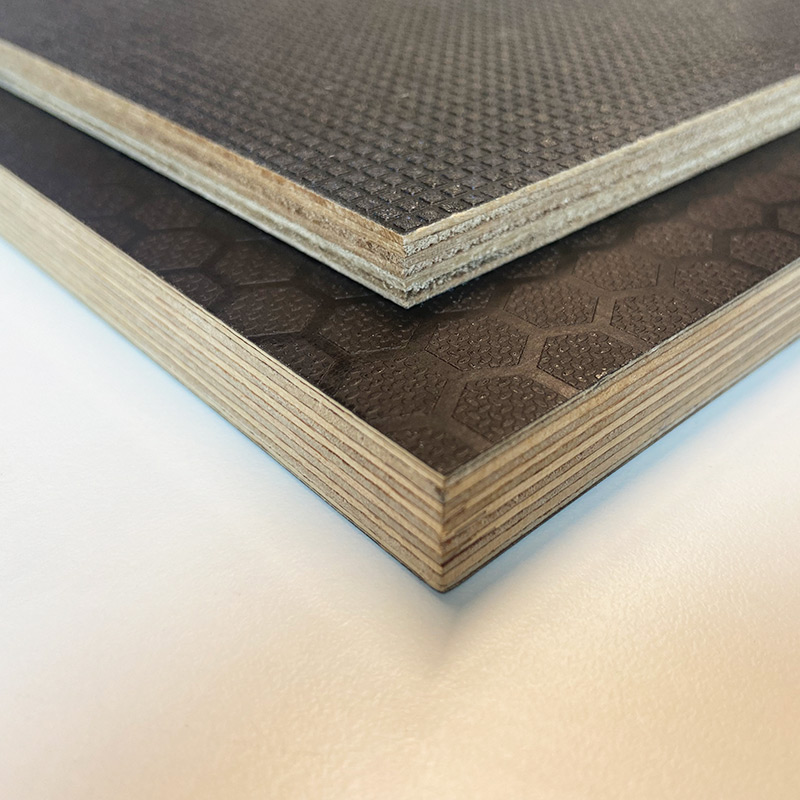

-Waterproof performance and wear & tear resistant

-Doesn't get corroded by concrete

-Exclusive hard-wearing and durability

-Easy to dismount,release agent free, nonstick cement,smooth finishing

-Resistance to decay and fungal infection

-Opportunity to use different wood to meet your demand

-Reduces the plastic surface absorption of the humidity of the board

-Avoiding bleeding out remains of bubbles and concrete.

Applications

-Building & construction

-Furniture manufacturing

-Playground manufacturing

-Internal & external design

-Hoardings and fencings

-Vehicle industry

-Wagon-building

-Shipbuilding

-Packaging

Specifications

| Dimensions, mm | 1220x2440,1250x2500,1220x2500 | |||||||

| Thickness, mm | 12,15,18,21,24,27,30,35 | |||||||

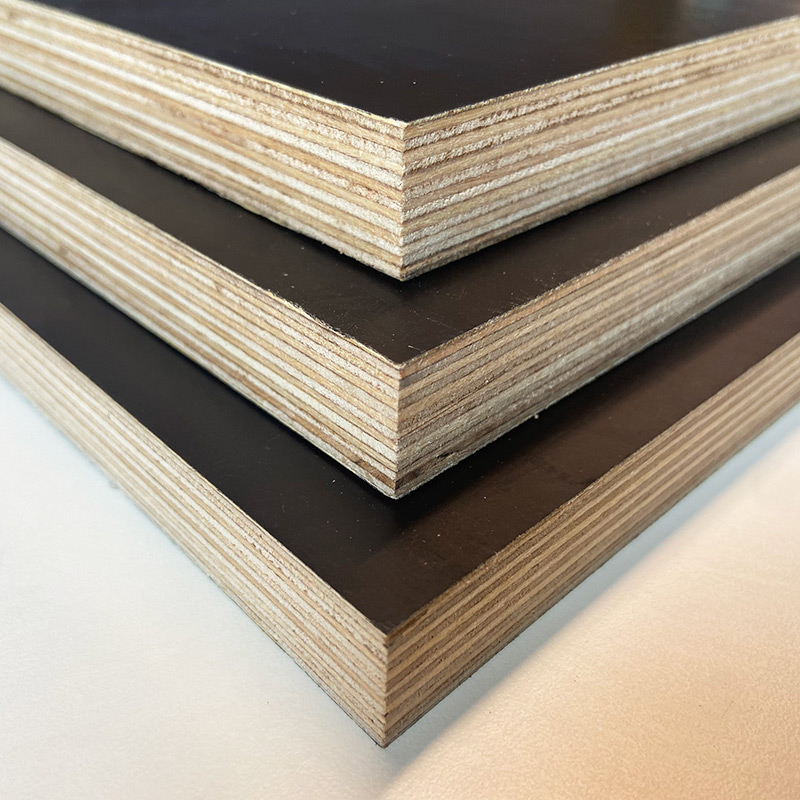

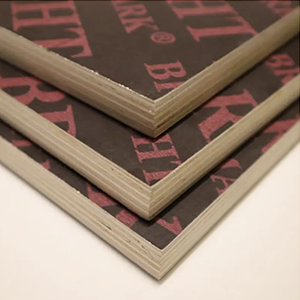

| Surface type | smooth/smooth(F/F) | |||||||

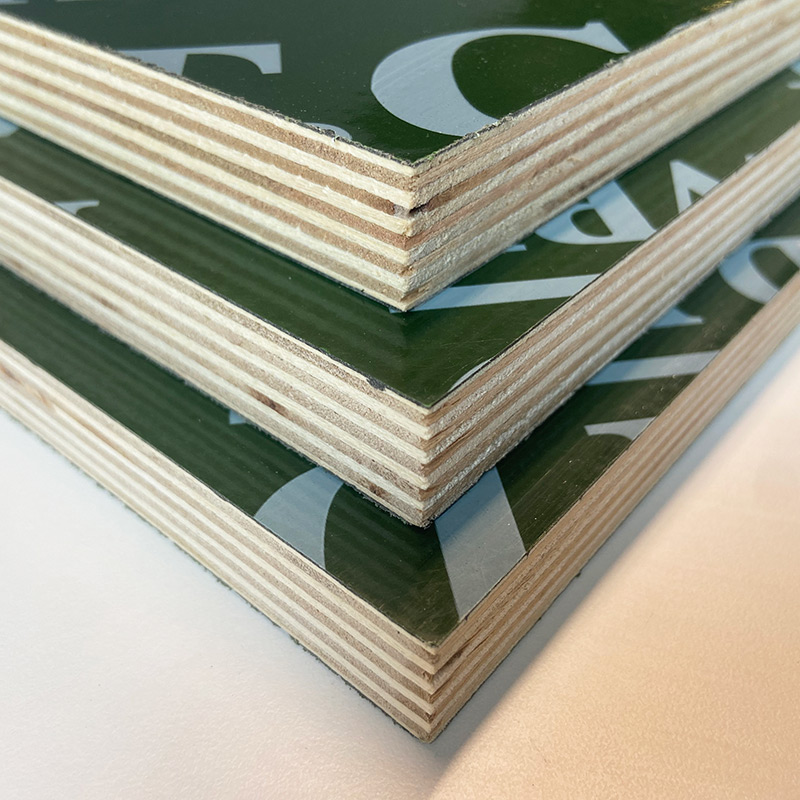

| Film colour | green, blue | |||||||

| Film thickness, mm | 0.5mm PP | |||||||

| Core | birch/eucalyptus/combi | |||||||

| Glue | phenolic WBP (type dynea 962T),melamine WBP | |||||||

| Formaldehyde emission class | E1 | |||||||

| Water resistance | high | |||||||

| Density, kg/m3 | 550-700 | |||||||

| Moisture content, % | 5-14 | |||||||

| Edge sealing | acryl-based water resistant paint | |||||||

| Certification | EN 13986, EN 314, EN 635, EN 636, ISO 12465, KS 301, etc. | |||||||

Strength indicators

| Ultimate static bending strength, min Mpa | along the grain of face veneers | 60 | ||||||

| against the grain of face veneers | 30 | |||||||

| Static bending elasticity modulus, min Mpa | along the grain | 6000 | ||||||

| against the grain | 3000 | |||||||

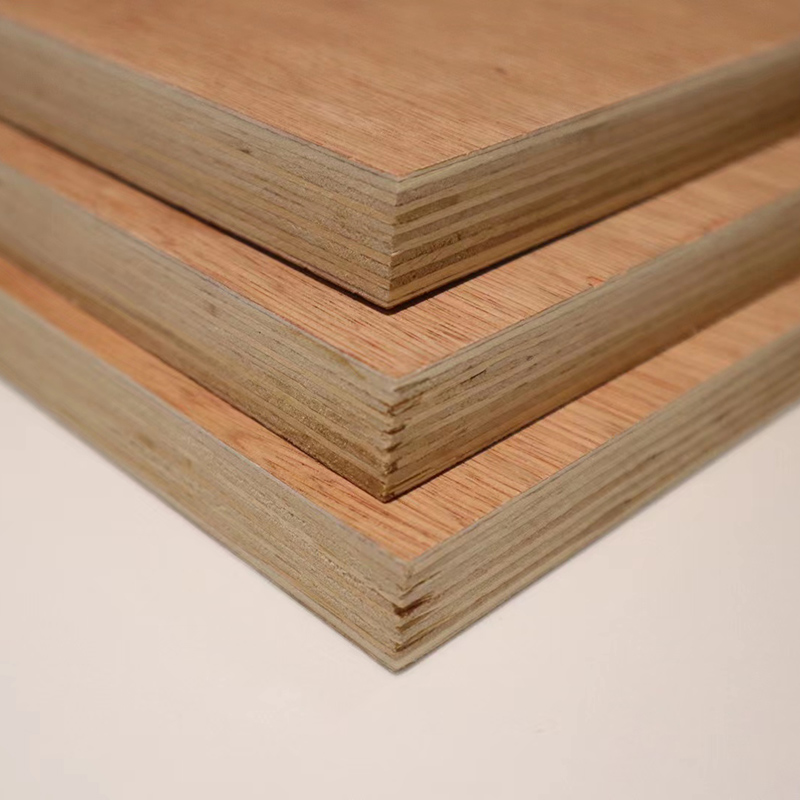

Number of Plies & tolerance

| Thickness(mm) | Number of Plies | Thickness tolerance |

| 12 | 9 | +0.5/-0.7 |

| 15 | 11 | +0.6/-0.8 |

| 18 | 13 | +0.6/-0.8 |

| 21 | 15 | +0.8/-1.0 |

| 24 | 17 | +0.9/-1.1 |

| 27 | 19 | +1.0/-1.2 |

| 30 | 21 | +1.1/-1.3 |

| 35 | 25 | +1.1/-1.5 |