Features

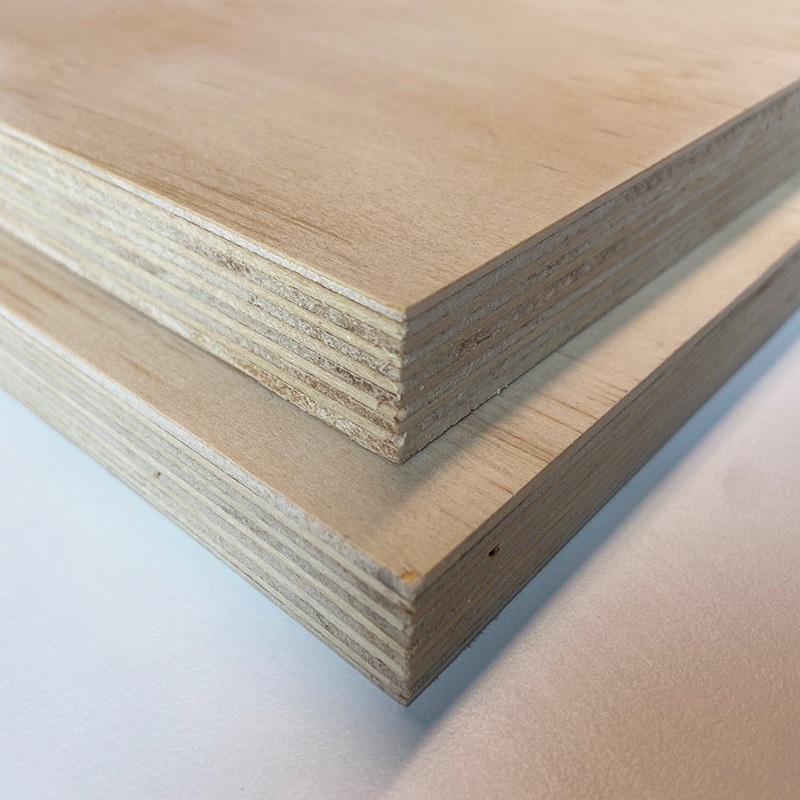

-100% eucalyptus veneer

-High hardness of a surface

-Excellent durability and strength

-Good resistance to most aggressive environments, including chemicals

-Higher water-resistance

-Fine and smooth sanded surface

-Opportunity to combine with other materials

-Improved strength and resistance to loss of bond strength with time

-Suitable for permanent use in humid conditions

-Suitable for temporary use in wet conditions

Applications

-Furniture

-Shopfitting

-Resilient packaging

-shipbuilding

-Van lining

-Cupboards

Specifications

| Dimensions,mm | 1220x2440, 1250x2500, 1220x2500 | |||||||

| Thickness,mm | 2-30 | |||||||

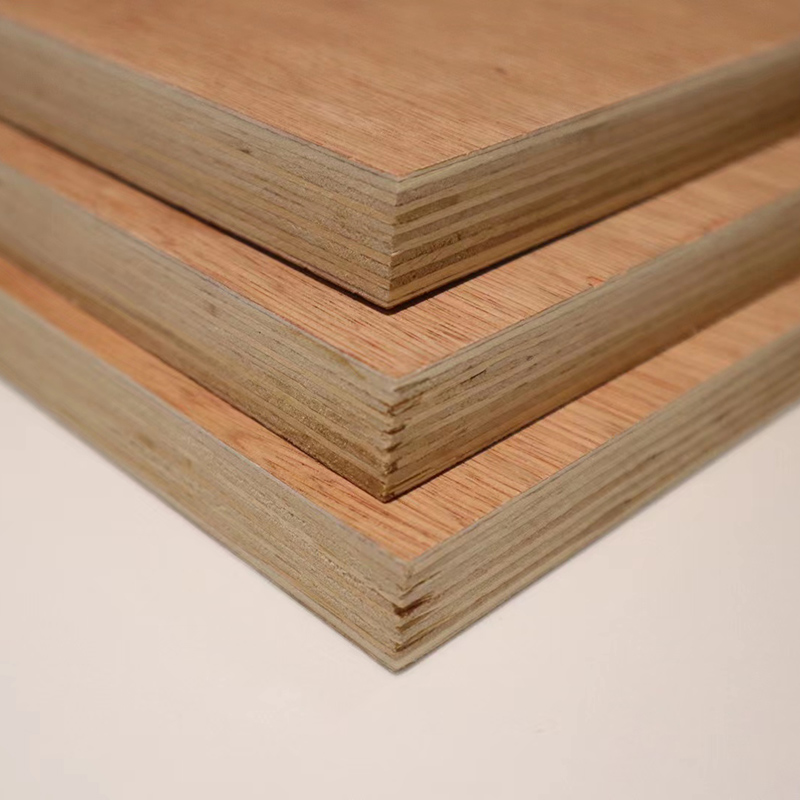

| Surface type | birch, pine, bingtangor, okoume, sapele, oak, ash, etc. | |||||||

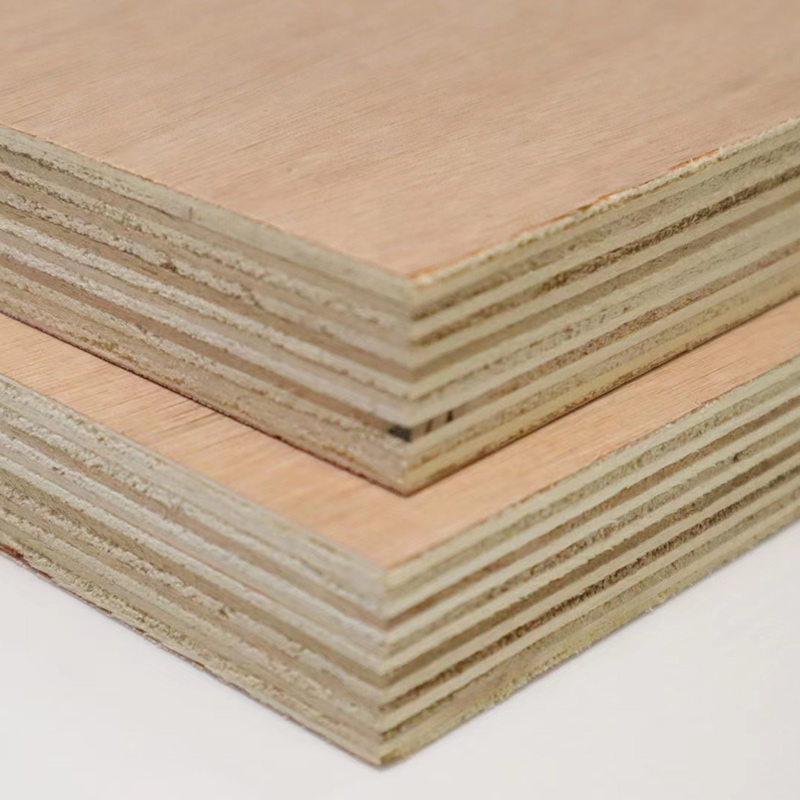

| Core | pure eucalyptus | |||||||

| Glue | E0, E1, E2, CARB, on request | |||||||

| Water resistance | high | |||||||

| Density,kg/m3 | 600-650 | |||||||

| Moisture content,% | 5-14 | |||||||

| Certification | EN 13986,EN 314,EN 635,EN 636,ISO 12465,KS 301,etc. | |||||||

Strength indicators

| Ultimate static bending strength,min Mpa | along the grain of face veneers | 60 | ||||||

| against the grain of face veneers | 30 | |||||||

| Static bending elasticity modulus, min Mpa | along the grain | 6000 | ||||||

| against the grain | 3000 | |||||||

Number of Plies & tolerance

| Thickness(mm) | Number of Plies | Thickness tolerance |

| 2 | 3 | +/-0.2 |

| 3 | 3/5 | +/-0.2 |

| 4 | 3/5 | +/-0.2 |

| 5 | 5 | +/-0.2 |

| 6 | 5 | +/-0.5 |

| 9 | 7 | +/-0.5 |

| 12 | 9 | +/-0.5 |

| 15 | 11 | +/-0.5 |

| 18 | 13 | +/-0.5 |

| 21 | 15 | +/-0.5 |

| 24 | 17 | +/-0.5 |

| 27 | 19 | +/-0.5 |

| 30 | 21 | +/-0.5 |