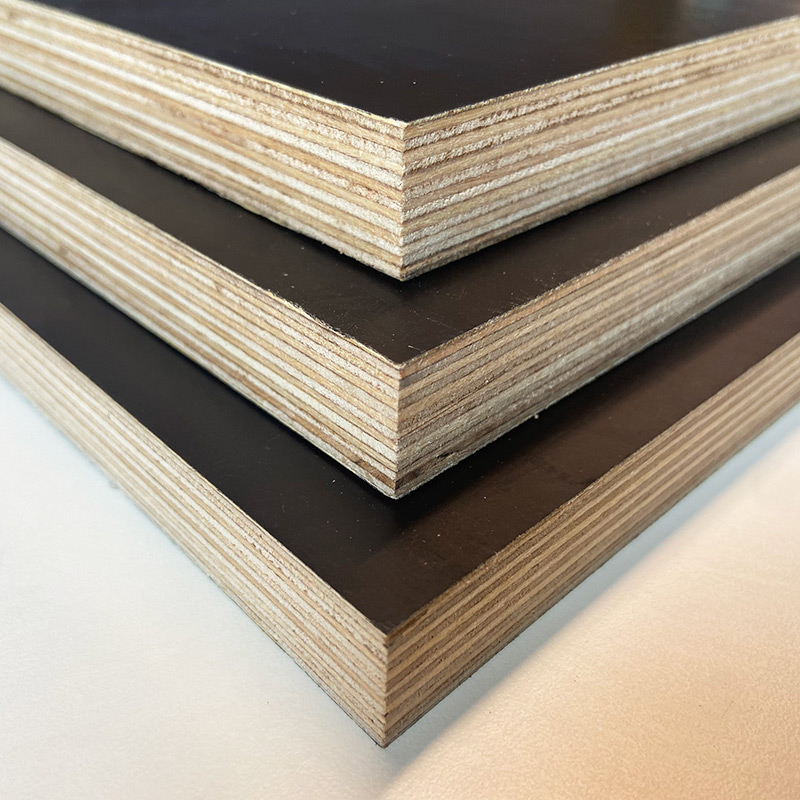

Poplar core film faced plywood finds application in conditions of high temperature drop, influence of moisture and detergent cleaning. It has light weight, resistant to corrosion attack, easily combined with other materials and simple in processing.

Film facing of plywood and edge treatment by waterproof paint ensure the water-and wear-resistance. poplar is used for construction plywood and also construction grade lumber. Because paint and glue take to poplar exceptionally well, it is also used frequently in woodworking projects, as well as cabinets and drawers.

High-quality films ensures hardness and damage resistance with local rich poplar tree sources and attractive price make it very competitive and widely demanded all over the world.

Features

-High water-resistance

-Resistant to moisture, temperature variation, chemicals and detergents

-Exclusive hard-wearing and durability

-Fast mounting and easy processing

-Opportunity of combination with other materials

-A wide variety of thicknesses and sizes

-Resistance to decay and fungal infection

-Strong flexibility

-High cost performance

-Rich poplar tree resources

Applications

-Building & construction

-Furniture manufacturing

-Playground manufacturing

-Internal & external design

-Hoardings and fencings

-Vehicle industry

-Wagon-building

-Shipbuilding

-Packaging

Specifications

| Dimensions, mm | 1220x2440,1250x2500,1220x2500 | |||||||

| Thickness, mm | 6,8,9,12,15,18,21,24,27,30,35 | |||||||

| Surface type | smooth/smooth(F/F) | |||||||

| Film colour | brown, black, red | |||||||

| Film density, g/m2 | 180 | |||||||

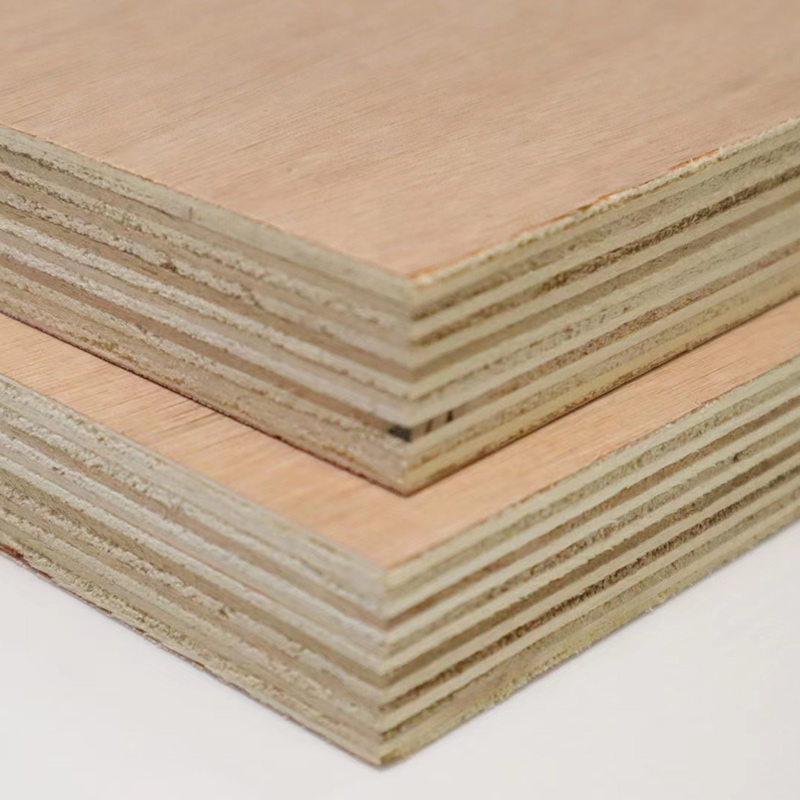

| Core | eucalyptus mix with poplar | |||||||

| Glue | melamine WBP | |||||||

| Formaldehyde emission class | E1 | |||||||

| Water resistance | high | |||||||

| Density, kg/m3 | 530-550 | |||||||

| Moisture content, % | 5-14 | |||||||

| Edge sealing | acryl-based water resistant paint | |||||||

| Certification | EN 13986, EN 314, EN 635, EN 636, ISO 12465, KS 301, etc. | |||||||

Strength indicators

| Ultimate static bending strength, min Mpa | along the grain of face veneers | 60 | ||||||

| against the grain of face veneers | 30 | |||||||

| Static bending elasticity modulus, min Mpa | along the grain | 6000 | ||||||

| against the grain | 3000 | |||||||

Number of Plies & tolerance

| Thickness(mm) | Number of Plies | Thickness tolerance |

| 6 | 5 | +0.4/-0.5 |

| 8 | 6/7 | +0.4/-0.5 |

| 9 | 7 | +0.4/-0.6 |

| 12 | 9 | +0.5/-0.7 |

| 15 | 11 | +0.6/-0.8 |

| 18 | 13 | +0.6/-0.8 |

| 21 | 15 | +0.8/-1.0 |

| 24 | 17 | +0.9/-1.1 |

| 27 | 19 | +1.0/-1.2 |

| 30 | 21 | +1.1/-1.3 |

| 35 | 25 | +1.1/-1.5 |